A concrete curing tank, also known as a concrete curing chamber or concrete curing box, is a specialized container used to provide a controlled environment for the curing of concrete specimens. It is typically used to facilitate the proper hydration and development of strength in concrete samples.

The main purpose of a concrete curing tank is to maintain specific temperature and moisture conditions that promote optimal curing of concrete specimens. This controlled environment helps prevent moisture loss from the concrete, which is essential for the hydration process. It also allows for the proper development of strength, durability, and other desired properties in the cured concrete.

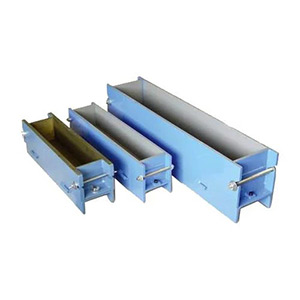

Concrete curing tanks are usually made of stainless steel to withstand the moisture and potential chemical reactions with the concrete. They are available in various sizes, ranging from small containers for individual specimens to large tanks that can accommodate multiple samples simultaneously.

To use a concrete curing tank, the freshly cast concrete specimens are placed inside the tank and sealed to prevent moisture evaporation. The tank is then filled with water or a moist environment is created using a humidification system. Additionally, temperature control mechanisms, such as electric heaters, refrigeration unit or temperature controllers, can be employed to maintain the desired curing temperature.

An accelerated curing tank is a specialized equipment used in the construction industry to speed up the curing process of concrete specimens. It provides controlled conditions of heat and moisture to accelerate the hydration reactions and promote the early strength gain of concrete. Accelerated curing tanks are often used in quality control laboratories and construction sites where there is a need to test or produce concrete samples quickly.

By subjecting the concrete specimens to elevated temperatures, typically ranging from room temperature to 110 degrees Celsius and maintaining high humidity levels, the accelerated curing tank allows the concrete to gain strength faster than it would under normal curing conditions. This enables faster testing of concrete samples and shorter construction timelines in certain applications.

Note: Specifications and dimension are customizable as per user's requirement.